For some time now, Automation World has been writing about how the future of automation will hinge on developments at the embedded layer (see links at bottom to a few of those recent articles). Those articles largely focused on the capabilities of modern microprocessors and the expanded possibilities they bring to automation devices of all types.

One aspect we haven’t covered to a great degree—but which happens to be as critical to the embedded layer as microprocessor power—is isolation. Isolation is the physical separation of one part of a circuit from another via a transformer, capacitor, optocoupler or other device to prevent direct current and unwanted alternating currents from passing between different parts of a system while allowing signal and power transfer. Essentially, isolation ensures that automation devices such as sensors, actuators, motors, robots, control units, and other factory equipment are protected from power irregularities and shielded from signal interference so they can operate reliably.

Mark Morgan, technologist and CTO of Advanced Development at Texas Instruments, says, “Among the most important [integrated circuit (IC)] innovations is the use of integrated capacitors as isolators in ICs that are packaged in multichip modules. Using such isolation products, system manufacturers can create better-protected circuitry for power, communications, and control. These systems, in turn, help distribute intelligent automation throughout the factory floor, bringing higher quality, cost control and energy efficiency, along with increased worker productivity and safety.”

Protecting automation devices via isolation is critical to your plant’s uptime because equipment operating on line power “may be subject to high-voltage surges and extreme transient spikes,” says Giovanni Frattini, manager of Texas Instruments’ Kilby Labs Design Center in Milan, Italy. “Line voltage disruptions can occur when heavy equipment, such as motors, power on or change loads; and electronic noise can interfere with signals in the control circuitry, potentially causing operational problems. Besides entering the system from outside, noise may also originate from within, so isolation must prevent noise feedback as well as entry.”

To address the isolation issue in automation devices such as intelligent sensors and programmable logic controllers (PLCs) requires the combination of robust performance from isolating elements as well as smaller size. “Small-footprint sensors are increasingly incorporated in processes for temperature, moisture, vibration, chemical and other types of control,” says Morgan. “In these systems, low-current circuitry must isolate high-frequency microcontrollers and wireless transmission, as well as sensing elements that are subjected to external conditions (see “Sensor with Isolation” graphic).

Morgan points out that the isolation issue with PLCs deals with their use to regulate multiple units on the factory floor as well as being networked to plant offices. With all these systems operating on multiple voltage levels, there is continual demand rescaling to pack in more channels for greater operational control in the same space. In addition, new high-speed communications in PLC backplanes require reduced signal latency for greater bandwidth. Isolation permits these complex systems to operate without mutual interference, as depicted in the “PLC with Isolation” graphic.

The challenge today, according to Morgan, is to find more effective ways to rescale traditionally bulky isolating components and integrate them on a chip, while at the same time improving signal bandwidth and lowering latency. “Miniaturizing components while improving their characterization is a difficult goal in itself, but integration also introduces into the IC package the same power and signal interferences that are meant to be kept away by the isolators,” he says.

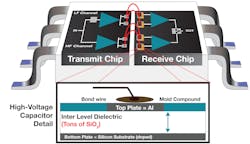

This issue is being addressed largely with the use of capacitors. Frattini says that, “of the various components used as isolators, capacitors are the most straightforward to integrate. The technology for integrating capacitors on a silicon die is well understood and the silicon dioxide that provides on-chip insulating layers is an excellent dielectric. However, the speeds that are operative still require isolation between high- and low-frequency circuits that can be achieved only by using separate chips.”

The solution, says Frattini is a multi-chip module (MCM), where “high-frequency circuitry resides on one chip and lower-frequency circuitry on the other. Bond wires between the two devices connect to capacitive pads that isolate incoming signals before relaying them to internal circuitry.”

Texas Instruments’ ISO78xx multichannel digital isolators are an example of a recently introduced IC product that uses this technology to provide capacitor-based reinforced isolation. These multichannel digital isolators provide protection for up to 8000 volts at peak and transmission speeds up to 100 megabits per second.

“MCMs like these save space and provide reinforced isolation that meets industrial specifications,” says Morgan.

Recent Automation World coverage of the embedded space

Leaders relevant to this article: