At the ARC Industry Forum earlier this year, the folks from Bedrock Automation were noticeably excited about the latest hardware release they were letting us get a peek of. Today, they’re sharing those developments publicly, so we can finally talk a bit about it.

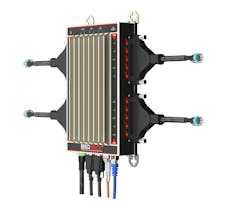

The company that built its technology on intrinsic cybersecurity has maintained the performance of its Open Secure Automation (OSA) system, but has shrunk it down into a smaller, standalone module with edge capabilities. Configured with the standard Bedrock IEC 61131-3 engineering tools, the Bedrock OSA Remote combines a programmable logic controller (PLC), remote terminal unit (RTU) and edge capabilities; universal I/O; and, of course, intrinsic cybersecurity.

“We’re taking all that technology and infrastructure and putting it in a PLC/RTU footprint,” commented Chris Harlow, technical support consultant, when we met back in February. Although it simplifies control in many ways, it was no easy feat to achieve. “To scale down to 20 I/O points in this footprint was a massive undertaking. Making it simple was a whole other massive challenge.”

Scaling the system down makes the OSA better suited to remote monitoring and control applications. “Many users automating remote operations in public utilities, oil and gas pipelines and other applications have wanted the intrinsic security, software-definable I/O, open engineering environment, and high performance of our Bedrock OSA system, but needed fewer than 20 I/O and thus did not need the higher channel count and redundancy our backplane provides,” said Albert Rooyakkers, founder and CEO of Bedrock. “For those applications, we have packed our core Bedrock functionality into a unified small footprint. This drives to record lows the cost of engineering, implementing, operating and securing edge automation, reducing barriers to IIoT and Industry 4.0 business innovation.”

With a starting price of $2,900 for the 10-channel model, the Bedrock OSA Remote comes at a price point that is below conventional mini PLCs or RTUs. The 20-channel model starts at $3,900. Total cost of ownership is also driven down by the cybersecurity, universal I/O, small footprint, open connectivity, free engineering software, broad temperature operating range and computing power, as the company details:

- Universal I/O. Each OSA Remote channel can be programmed for analog, discrete and digital connectivity supporting a wide range of communication protocols. This reduces engineering time, maintenance and spares management significantly.

- Open connectivity. Much of the benefit of the Industrial Internet of Things (IIoT) and Industry 4.0 innovation depends on open connectivity, but that comes with risk. Bedrock OSA Remote provides a secure supervisory control and data acquisition (SCADA) uplink for OPC UA, and will also support MQTT and DDS later this year.

- Small footprint. In addition to needing fewer modules because of its programmability, OSA Remote's small size—137 x 226 x 59 mm—takes up minimal cabinet real estate, which is important in remote areas where space is at a premium.

- Free engineering software. Bedrock Automation provides IEC 61131-3 standard software that is free for an unlimited number of users.

- Broad temperature range. All Bedrock OSA Remote controllers operate at temperature ranges of -40 to 80 °C without fans or forced draft. This means the monitoring and control can be extended further with lower cost and higher reliability.

- Computing power. With an array of cybersecure and multicore ARM processors, 512 MB of RAM, 8 or 32 Gb Flash, MRAM for retained variables and a supercapacitor to retain firmware for years without power, OSA Remote has the computation and communication bandwidth needed to run the advanced edge control and analytical software expected in a modern deployment of automation.

- Intrinsic cybersecurity. In addition to avoiding costly and potentially dangerous cyber intrusion, Bedrock intrinsic cybersecurity reduces the need for costly external firewalls, intrusion detection and other devices. Everything is embedded into OSA Remote so in addition to securing its own controls, it can extend protection to other systems and devices via embedded anomaly detection and can even function as a secure proxy to protect legacy controls.

Implementing open control solutions at the edge also offers the potential to deliver financial benefits for end users by flattening automation hierarchies to eliminate much of the cost and effort it might otherwise take to maintain and operate those layers, according to Mark Sen Gupta, director of research for ARC Advisory Group. “But the company also recognizes that unless this openness is protected from cyber threats, all the elegance of open solutions could be for naught,” he said. “Bedrock Automation’s OSA Remote is that company's solution for secure edge control in remote sites.”

Bedrock owes much of the ability to scale the system down to the “tiny ASIC chip” that’s at the center of the system. Sourcing processors internally through parent company Maxim Integrated gives Bedrock more control over those capabilities. “We can design our own chips to do what we want to do,” Harlow commented, adding that it’s also a fundamental aspect of the built-in security—being able to control the chain of custody all the way from the silicon. “It becomes the root of trust. The chip at the center can authenticate everything else.”

Leaders relevant to this article: