The digital transformation of industry is a topic more often discussed as a technological opportunity than a real-world applications. However, at the 2019 Emerson Exchange event in Nashville this week, 3M and Celanese explained how they’ve actively started their digital transformation using analytics software.

Robert Sentz, manufacturing technology engineer at 3M, said the company was facing a perfect storm—aging equipment, a less-experienced workforce, increased demands on production, and questions around the sustainability of their environmental health and safety programs. 3M developed a digital transformation vision called PACESetter at the corporate level after realizing it confronted similar issues across all its plants. PACESetter focuses on: developing Proprietary process technologies with Six Sigma quality and cycle time; Automation to enable no-touch processes as much as possible; use of Connected technologies to drive rapid process and product control; delivering Efficiencies via a lean continuous flow; and providing a Safe and sustainable approach.

After first assessing where its plants stood technologically compared to its goals, Sentz said 3M chose to focus on four areas:

- Batch automation and control systems, including batch analytics and process modeling, batch recipe control of products, advanced process interlocking, Delta V Digital Twin operator training, and alarm rationalization,

- Process analytical technology for online real-time analysis, including use of near infrared, Fourier transform infrared, and viscometers,

- Operator-guided workflow based on standard work practices, and

- Use of analytics to extend the life of existing equipment assets.

“We executed this strategy by piloting different technologies at different plants to get quick wins,” said Sentz. The company opted for this dispersed application of technologies because it’s important to not try to implement them all at one plant at once. "If you do, nothing will get done,” Sentz added.

This process began in 2017 and 2018 at three plants, with the first piloting Emerson’s AMS Device Manager with ValveLink and Smart Meter verification, the second piloting Emerson’s Process Analytical Technology and PlantWeb Advisor, and the third piloting Emerson’s Workflow, Wireless Vibration, and PlantWeb Insight. As pilots were successfully completed at one plant, they were rolled out to the other two.

“Operations staff was involved early in this process at each plant, with workshops and the evaluation of work practices,” Sentz noted.

Some of the benefits cited by Sentz include increased production volumes from existing equipment as well as extended lifetimes, which helped defer the purchase of new reactor systems. “All of this has helped us move from addressing issues with point solutions to delivering holistic solutions," he said. "And, by enabling us to track and report progress in each category, it has helped us create a roadmap for our digital transformation. It also led to the development of strategic partnerships and the creation of internal teams to solve specific manufacturing issues.”

At Celanese, the problem was stranded data, explained Greg Aguilar, senior principal instrument engineer. To address this, Celanese identified five potential use cases (from an initial pool of 54) that could benefit from broader sharing of device data. It then prioritized those cases based on their impact and feasibility. Following this evaluation, it was decided to first target two of the five applications—predictive maintenance and process optimization.

With this focus, Celanese began looking seriously at 43 vendors in the Industrial Internet of Things (IIoT) space. The company ultimately narrowed its choice down to Emerson because of its KNet analytics platform and reliability expertise that Celanese didn’t find elsewhere, said Aguilar.

According to Emerson, KNet uses libraries of advanced statistical and machine learning algorithms to put operations technology (OT) and information technology (IT) data into context to improve decisions around process and asset performance.

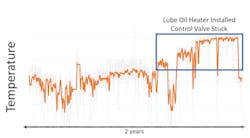

Insights from KNet analytics paid off early for Celanese in the predictive maintenance use case. As they looked at one piece of equipment over a two-week and two-month time frame, Aguilar explained, there was very little change in the temperature level. Plus, the temperature remained well below the alarm level. But when they examined the analytics over a two-year period, they could see that the “normal” temperature level was significantly higher than it had been previously.

Armed with this information, they were able to determine that the cause of the slowly rising temperature was a stuck valve on the lube oil heater. The rise in temperature wasn't noticeable when looking at day-to-day or week-to-week data, said Aguilar. But having this temperature rise continue to go unnoticed could result in long-term bearing or shaft damage and even a shutdown of the unit, he added. “Experiencing an early success like this really built our confidence in the technology, which meant that we did not have to push the technology down from corporate to the site because the operators wanted to use it,” Aguilar said.

As insights from KNet continue to be delivered, Celanese is using a codified model to transfer knowledge to other sites. "In this process, we’re building institutional knowledge and spreading it across the company,” said Aguilar, adding that communicating insights in this manner provides a launching pad for sites to innovate on.

Like 3M, Celanese involved operators early in its process. “The 54 work cases we initially came up with were developed with input from operations to address the specific pain points they experience,” said Aguilar. “Operators were included in the brainstorming to identify solution providers, as well as the rules and models we follow. They were value-added partners in the whole process.”

Leaders relevant to this article: