Fewer Standstills, More Throughput, Lower Costs

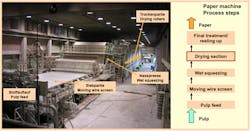

Since 1999 the mill has been gradually modernized to boost its efficiency without compromising its consistently high product quality. The key measures include the change from a time-based to a condition-dependent (preventive) maintenance of the PM 7 through the introduction of FDT/DTM technology.