One of the primary drivers behind the growing adoption of Ethernet on the plant floor is the simple fact that everyone is familiar with it. But not all Ethernet is the same. There are some distinct differences at the physical layer — cabling and connectors — that set industrial Ethernet apart from its commercial counterparts.

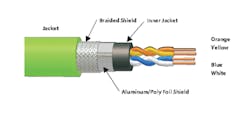

Some of the more common aspects of industrial Ethernet cabling include: 4x22 AWG, TC braid and foil shield, PVC and TPU jacketing, and stranded and solid conductors. Wiring inside the cable can be in two twisted pairs or as two star-quad pairs.

Aside from the physical layering of the cables, perhaps the biggest differentiator between commercial and industrial Ethernet is at the connector level. Though the common RJ45 connector used in commercial applications can also be found in industrial Ethernet, the connector is typically reinforced in some way. Both 8 pin and 4 pin types are used in both male and female configurations available in molded or filed wireable versions. They are also commonly offered in IP20- and IP67-rated versions.

A bayonet-style mating interface on IP67-rated RJ45 offers industrial strength protection for the connector. Plus, the quarter turn required to connect the cable to the node mates the RJ45 plug to the outlet and ensures that it is properly locked and sealed.

Beyond RJ45 connectors, M12 and M8 style connectors are also used for industrial Ethernet connections. The M12 connector is available as a 4- or 8-pole connector and can offer IP67/IP69K protection. Like RJ45, M8 and M12 connectors are available as molded or field wireable connections.

One of the more recent developments to emerge on the industrial Ethernet connector scene is the X-Code connector. X-Code connectors are distinguishable by the way in which the 8 wires in the Ethernet cable are segmented into 4 shielded pairs. This connector types has developed to keep pace with the increasing use of Gigabit Ethernet on the plant floor. Harting, Phoenix Contact, Metz and Escha have released this type of connector and Turck expects to release M12 and RJ45 field wireable X-Code connectors in Q3 2012.