Interest around industrial wireless has been a hot topic for much of the past decade. However, most such applications have been used to position sensors in places that are difficult to reach with wiring or on rotating machinery. In other words, wireless has not so much been the preferred industrial networking option as it has been the most convenient option for difficult networking tasks.

But the rise in interest in the Internet of Things (IoT) could be changing that.

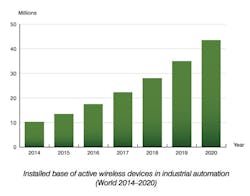

According to Berg Insight, a dedicated machine-to-machine/IoT market research firm based in Sweden, the installed base of wireless IoT devices in industrial automation reached 10.3 million in 2014. The report predicts that the number of wireless IoT devices in automation networks will grow at a compound annual growth rate (CAGR) of 27.2 percent to reach 43.5 million by 2020.

“Companies are now deepening the integration between industrial automation systems and enterprise applications and the promise of IoT is getting more tangible by the day,” says Johan Svanberg, senior analyst, Berg Insight.

The rise in deployment of Ethernet-based networks in factory automation is one of the key drivers for the popularity of Wi-Fi in such applications, according to Berg Insight. Also noted in the report is how the increased use of tablets and smartphones for mobile HMI applications has been another important driver for the adoption of Wi-Fi—as well as Bluetooth—in automation equipment.

In the process industries, Berg Insights points to 802.15.4-based standards such as WirelessHART and ISA100.11a as the major contenders.

Cellular connectivity has also been playing an increasingly important role in wireless deployments across both factory automation and process industry applications. Cellular most often plays a part in remote monitoring in the process industries (such as remote wellheads) and for backhaul communication between plants.

Innovations in sensor technology, wireless connectivity, energy harvesting, Big Data and Cloud Computing are all part of the seamless exchange of information between devices, systems and people, which paves the way for improved performance, flexibility and responsiveness throughout the enterprise value chain, Svanberg adds.

The report from Berg Insight looks at the major applications for wireless IoT in industrial automation, the top wireless IoT device and system providers, the impact these technologies will have on the market, and how connectivity strategies in industrial automation is expected to evolve. To download the report, visit: www.berginsight.com/ReportPDF/ProductSheet/bi-ia2-ps.pdf

Leaders relevant to this article: