In order for the Industrial Internet of Things (IIoT) to truly take off, connecting devices to the cloud—or on the edge of the network— needs to be fast, easy and affordable. It is also important that the suppliers of automation technology embrace open standards so that these “things” are interoperable.

Manufacturers have already seen some clear examples of how products must evolve for the future of the Internet of Things (IoT). Opto 22, for one, has been adding RESTful APIs and Node-RED graphical development capabilities to its programmable automation controllers (PACs) as well as to its groov appliance for building mobile operator interfaces.

This week, Opto 22 takes its commitment to open standards a step further with the announcement that it has joined The Linux Foundation as a silver level member. According to Opto 22, this strategic move is the company doing its part to “spearhead the adoption of open-source technology in the industrial automation and process control industries, and accelerate the rollout of Industrial Internet of Things application.”

In addition, Opto is one of the 50 founding members of the EdgeX Foundry, a new Linux Foundation open source project announced today at Hannover Messe. The goal of EdgeX is to build a common open framework for IoT edge computing and a community of companies offering plug-and-play components that can be combined to quickly create secure IoT solutions that can easily be scaled.

Why is this important? Because there will be over 20 billion connected things in use globally by 2020, according to Gartner, and the sheer quantity of data that will be transmitted from these devices is driving adoption of edge computing—where connected devices and sensors transmit data to a local gateway device instead of sending it back to the cloud or a central data center.

Edge computing allows for quicker data analytics and reduced network traffic. This is essential for applications that require localized, real-time data analysis for decision-making such as factory optimization, predictive maintenance, remote asset management, building automation, fleet management and logistics.

But while IoT and edge computing can deliver significant business value through automation and analytics, widespread fragmentation and the lack of a common IoT framework are hindering broad adoption and stalling market growth.

“Businesses currently have to invest a lot of time and energy into developing their own edge computing solutions before they can even deploy IoT solutions to address business challenges,” said Philip DesAutels, senior director of IoT at The Linux Foundation and executive director of EdgeX Foundry. “EdgeX will foster an ecosystem of interoperable components from a variety of vendors, so that resources can be spent on driving business value instead of combining and integrating IoT components.”

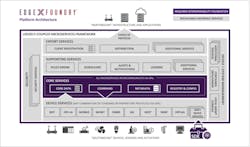

Designed to run on edge computing devices such as PACs and mobile-ready HMIs, the EdgeX platform can quickly and easily deliver interoperability between connected devices, applications, sensors and services, across a wide range of use cases.

Founding platinum member Dell is contributing its Project FUSE source code under Apache 2.0, consisting of more than a dozen microservices and over 125,000 lines of code, to seed the EdgeX Foundry project. Started in July 2015, Project FUSE was built with feedback from hundreds of technology providers and end users to enable developers to build proprietary products and value-added services on top of an open foundation.

EdgeX Foundry proposes a loosely-coupled tiered IoT architecture by allowing customers to deploy a mix of plug–and–play microservices on compute nodes at the edge depending on the capability of the host devices, where they sit in the solution stack, and the use case. Based on initial code contributions from founding members there is a fully-functional Alpha platform in the project today that will continue to mature in the community.

The benefits to EdgeX community members include:

End Customers: Deploy IoT edge solutions quickly and easily with the flexibility to dynamically adapt to changing business needs.

Hardware OEMs: Scale faster with an interoperable partner ecosystem and more robust security and system management. Hardware becomes easier to deploy and more widely supported with EXF.

ISVs: Interoperate with third-party applications and hardware without reinventing connectivity. Assemble complex solutions for certified and interoperable components.

Sensor/Device Makers: Write a device driver with a selected protocol once using the SDK and get pull from all solution providers.

System Integrators: Get to market faster with plug-and-play ingredients combined with individual innovations.

“Achieving cohesive, value-add Industrial IoT solutions is dependent on a successful ecosystem that can drive interoperability and digital transformation,” said Benson Hougland, vice president of marketing and product strategy for Opto 22. “Together with other EdgeX Foundry founding members, a common framework will be developed to help align IoT adoption and business objectives.”

EdgeX founding members include: Advanced Micro Devices (AMD), Alleantia, Analog Devices, Bayshore Networks, Beechwoods Software, Canonical, ClearBlade, CloudPlugs, Cloud of Things, Cumulocity, Davra Networks, Dell, Device Authority, Eigen Innovations, EpiSensor, FogHorn Systems, ForgeRock, Great Bay Software, IMS Evolve, IOTech, IoTium, KMC Controls, Kodaro, Linaro, MachineShop, Mobiliya, Mocana, Modius, NetFoundry, Neustar, Opto 22, relayr, RevTwo, RFMicron, Sight Machine, SoloInsight, Striim, Switch Automation, Two Bulls, V5 Systems, Vantiq, VMware and ZingBox. Industry affiliate members include: Cloud Foundry Foundation, EnOcean Alliance, Mainflux, Object Management Group, Project Haystack and ULE Alliance.

Leaders relevant to this article: