Bosch Rexroth Showcases its Flexible Transport System

Configurable high-speed transport systems have been moving beyond fulfillment center applications and into numerous manufacturing applications in line with the increase of low-volume, high-mix production operations that are growing in response to greater customization demands. The flexibility of these conveyance systems enables the rapid changeover applications increasingly demanded of manufacturers.

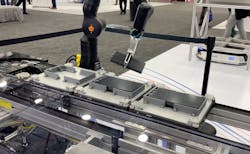

As part of a showcase of its ctrlX Core technology at Automate 2023, Bosch Rexroth highlighted its Flexible Transport System (FTS), a high-speed conveyance system for transporting and positioning materials and workpieces.

Demonstrating the FTS at the event, Alex Trees, applications engineer associate at Bosch Rexroth, noted that the ctrlX core, Bosch Rexroth’s app-based controller, is “the brains of this whole machine.” In the demo at Automate, ctrlX’s Cores PLC app was used as the PLC for the FTS.

According to Bosch Rexroth, the FTS fills a niche for applications where traditional rollers, chains or belt conveyance systems reach their limits. The freely programmable individual and synchronized movements of the FTS movers delivers faster conveyance speeds than traditional systems.

Trees pointed out the flexibility of the FTS saying it can be used for high-speed, high-force applications where you have a high payload, as well as with lower payloads or where you need higher accuracies. He added that “another cool thing about the FTS is that you can use it as a third axis—if you want to create a three-axis gantry, you can instead just create a two-axis gantry and use the FTS conveyor as your third axis of motion.”

The FTS is said to deliver extreme positioning accuracy, as well as high repeatability and bi-directional movement, through its use of sensors between the motors and the motion control system. The ctrlX Core software allows for the programming of all carrier movements as well I/O synchronization where required, enabling quick conversion to other products.

Key features of the FTS include:

- Independent movement of up to 32 carriers per track.

- Speeds from 0.02 m/s to 5 m/s.

- Ability to carry loads from 1 kg up to more than 1,000 kg.

- Provide a continuous force range from 60 N to 3000 N.

- Magnets that can withstand temperatures up to 158° F.

In the video below, Alex Trees with Bosch Rexroth demonstrates the Flexible Transport System.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: