Crossing the Interoperability Chasm

Despite the relative ease of digitally transforming manufacturing and processing operations due to technology advances and technology supplier cooperation over the past several years, effecting the change still requires a number of hurdles to be jumped. The ‘devil in the details’ aspects of the Industrial Internet of Things and Industry 4.0 is well illustrated in the rise of numerous groups designed to help smooth industry’s understanding and adoption of digitally connected industrial devices, systems, and networks.

Beyond the increasing support for open source software use across industry, some of the more well-known groups working to advance the idea of connected industry and open systems include the Open Process Automation Forum, the Open Industry 4.0 Alliance, and the Industrial Internet Consortium, which recently incorporated the Open Fog Consortium into its operation.

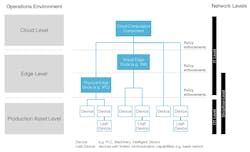

Another such group, the Open Manufacturing Platform (OMP), whose members include BMW Group, Microsoft, Cognizant, Red Hat, ZF Friedrichshafen, and Cap Gemini, recently released a white paper titled, “Insights Into Connecting Industrial IoT Assets.” This paper addresses the specific connectivity issues industry faces in the digital transformation, ranging from the connection of sensors, actuators, and machines to a central data center; lack of common standards and proprietary interfaces; and the gaps between operational technology (OT) professionals’ responsibility for the commissioning, operation, and maintenance of shop floor equipment and information technology (IT) personnel’s responsibilities for overall data processing, hardware and software infrastructure, and enterprise-wide IT strategy.

Members of the OMP group point out that the group was initially created to “harness the power of collaboration and openness so that raw equipment data can be collected, aggregated across multiple data sources, consolidated, and analyzed to create information.”

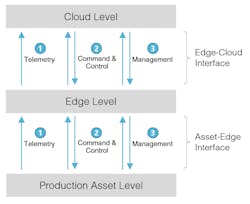

A key point in the paper focuses on production asset level connectivity, specifically highlighting the prominence of OPC UA and MQTT. According to the paper: “At the OT level, there are many different protocols. Specialized real-time protocols (like Profinet or Powerlink) are often not compatible with the IT systems since the first group often has different ISO/OSI layers than the standard Ethernet protocol commonly used by IT systems. For the connection between OT and IT levels, two standards have developed a wide adoption in the last years: OPC UA (Open Platform Communications Unified Architecture) and MQTT (Message Queuing Telemetry Transport). Both protocols are seen as common factory standards since they are vendor and hardware independent. Most OT device manufacturers have included at least one of these two protocols in their state-of-the-art products. This is the reason why this working group mainly focuses on these two protocols.”

The authors advocate for the use of OPC UA and MQTT because of OPC UA’s “widespread use in the manufacturing sector, self-describing behavior, data semantic standardization groups, and support for modern security standards. The OPC UA Foundation standardizes data exchange as a platform-independent, service-oriented architecture. If the implementation of OPC UA is not reasonable or applicable, the use of MQTT as a transport protocol is a valid alternative. The choice of data formats and transport protocols should be considered based on the specific use case. For example, for a lightweight IoT sensor, a complex OPC UA implementation may not be possible due to hardware limitations. If OPC UA or MQTT is not natively supported, an adapter on the production asset level is a good solution to transform data from the proprietary asset interface to OPC UA or MQTT. An alternate solution is the installation of a software adapter at the edge level where the data is filtered, combined, and converted to the northbound edge protocol (MQTT). The overall goal is to transform and harmonize the data as early as possible in the communication process.”

The bottom line here is that it is increasingly clear that OPC UA and MQTT are projected to be the key methods for open data communication on the plant floor and connecting with IT systems at the enterprise level and into the cloud for the foreseeable future.

Read more about MQTT and OPC UA here: