3 Big Industrial Networking Developments

Notable advances in industrial networking technology are not rare, but they usually arrive one at a time. Occasionally, however, we see a cluster of new developments, as we did in late 2018 when the OPC Foundation announced its work to bring Time-Sensitive Networking (TSN) to field level devices, CC-Link announced the availability of CC-Link IE TSN, and ODVA announced the ability to integrate HART communication protocol devices into an EtherNet/IP architecture. All of these major developments were announced at one event—the annual SPS event in Nuremberg, Germany.

There now seems to be another wave of new industrial networking announcements, this time surrounding Ethernet-APL, the Process Automation Device Information Model, and the Instrumentation Device Profile for OPC UA Field eXchange.

Ethernet-APL

Members of the APL Project, which includes the OPC Foundation, Profibus & Profinet International, FieldComm Group, and ODVA, announced the official availability of 10Mbit Ethernet-APL technology— the new two-wire, intrinsically safe Ethernet physical layer. This announcement was made to emphasize that Ethernet-APL technology now meets all requirements of the process industry.

APL Project participants worked closely with TüV, the certification body for intrinsic safety, to validate the developed explosion protection concepts and prepare for standardization of Ethernet-APL in the IEC.

To support implementation of Ethernet-APL technology in industrial automation and networking products, the APL Project has worked with semiconductor manufacturers to bring 10BASE-T1L Phy chipsets for Ethernet-APL to market. With the successful completion of the project, the APL Project says all interested companies can now integrate Ethernet-APL into their products.

The APL Project announcement notes that Ethernet-APL can be applied at multiple power levels with and without explosion hazardous area protection. Information about engineering guidelines and best practices for planning and installation, and conformance test specifications and test tools are available at www.ethernet-apl.org

PA-DIM

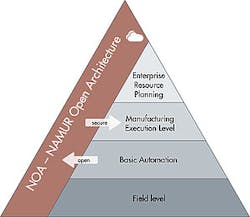

The Process Automation Device Information Model (PA-DIM) allows for communication of common process automation instrument parameters across any industrial networking protocol. This protocol agnostic approach is key to the integration of IT and OT (operations technology) systems.

Ownership of PA-DIM has now been expanded beyond FieldComm Group and the OPC Foundation to include ISA100 WCI, ODVA, Profibus/Profinet International, NAMUR, VDMA, and ZVEI. This move to expand ownership to these organizations was done to support the adoption of the OPC UA-based standard model for core field device information in process automation technologies.

The first version of the PA-DIM specification, published in 2020, includes an information model and semantic identifiers for common process automation instrument types including pressure, differential pressure, temperature, level, flow, and valve positioners. Current activity within the working group is focused on extending the model to include process analyzers.

OPC UA controller-to-device standard

To further multi-vendor interoperability of instrumentation devices based on OPC UA and the OPC UA FX (Field eXchange) extensions, the OPC Foundation and FieldComm Group have begun working together to develop a single standard for an interoperable interface between PLC (programmable logic controllers) and/or DCS (distributed control systems) and instrumentation devices such as transmitters, instruments, and actuators.

To support this work, the two organizations are developing an OPC UA Instrumentation Working Group, which is open to members of the OPC Foundation and the FieldComm Group. This group will focus on developing a new instrumentation device profile specification for OPC UA FX which will incorporate:

- commonly used interfaces and data types, including functional safety;

- diagnostic information specific to instrumentation devices;

- operation modes of instrumentation devices; and

- state machines and timing models for instrumentation-specific functionality.

The profile specification will use pub/sub communication and can be combined with underlying communication protocols, such as UDP/IP, and physical layers such as Ethernet-APL to support use in both discrete and process manufacturing applications. According to the OPC Foundation, this will address safety instrumentation based on OPC UA Safety and deterministic data exchange based on Ethernet Time-Sensitive Networking (TSN), where appropriate. The instrumentation facet of the specification will be complementary to PA-DIM.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: