The Foxboro Evo™ Foxboro Field Device Manager—Maximize your Uptime and Performance

Configure, commission, maintain and diagnose fieldbus devices throughout their entire lifecycle with our comprehensive, fully integrated engineering & maintenance environment. The Foxboro Field Device manager (FDM) user interface & diagnostic capabilities provide the means to increase uptime and performance while significantly lowering maintenance costs.

Truly Open Technology. FDM offers interoperability with any device, from any vendor, with any protocol. With Foxboro interoperability and anybus capabilities, you can maintain your preferences because the system adapts to you. The choice is yours!

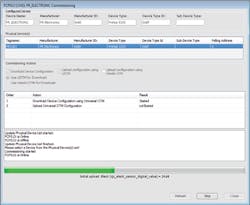

Unmatched device configuration, commissioning, and diagnostic support. FDM is the first to offer support for FDT & Enhanced EDDL, two technologies enabling device vendors to program device configuration & maintenance content for the host system. This greatly simplifies configuration, commissioning and maintenance while including advanced diagnostics to optimize your field devices.

Simplify engineering & increase productivity. Reusable engineering is provided through customizable templates for each device model. A Commissioning Wizard automates all the steps of device commissioning, making it easy to replace a failed device.

Eliminate wasted maintenance & reduce downtime. Moving to predictive device maintenance approaches helps you spot problems early, before they become severe, giving time to plan corrective action without downtime.

For more information, please visit: www.foxboro.com/foxboroevo/maintain