Terms can sometimes play tricks on the mind. Take EtherNet/IP, for example. Many people will read “IP” as internet protocol and think that EtherNet/IP refers to plain old, standard industrial Ethernet.

It doesn’t.

EtherNet/IP and standard industrial Ethernet are related, but not the same thing. Ethernet is the protocol for the physical layer that makes the connection to the network, and EtherNet/IP refers to an Ethernet-based industrial communications protocol managed by ODVA Inc., a member-based standards and trade organization.

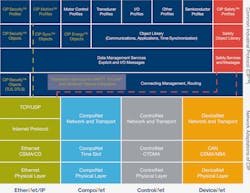

In EtherNet/IP, the IP stands for industrial protocol, which makes sense because EtherNet/IP relies on the Common Industrial Protocol (CIP), another industrial standard managed by the ODVA. CIP defines an object-oriented approach for presenting data, managing connections, and exchanging messages at the session, presentation, and application layers of the Open Systems Interconnection (OSI) model. As such, CIP fosters the integration of automation services and applications, such as control, synchronization, motion, and safety.

EtherNet/IP adapts CIP to work with key elements of standard Ethernet (IEEE 802.3 combined with the Internet Engineering Task Force’s TCP/UDP/IP suite). For example, it uses the transfer control protocol (TCP) and the user datagram protocol (UDP) at the transport layers—TCP for complex messages, such as those used in diagnostics, and UDP for simple messages, such as those used for I/O. IP packets route messages vertically through operations so the data can be consumed by manufacturing execution systems (MES), enterprise resource planning (ERP) software, and even cloud-based applications.

“Using TCP, UDP, and IP ensures that EtherNet/IP is IT friendly,” notes Steve Fales, director of marketing at ODVA. “Furthermore, the same class of switches and routers used in established enterprise networks can also carry EtherNet/IP OT (operations technology) traffic.”

Fales credits reliance on industry standards and the experience of ODVA’s diverse membership for making EtherNet/IP suitable for a range of industrial automation and control networks. “EtherNet/IP can accommodate everything from a single controller, machine, or skid to entire facility installations across discrete, hybrid, and process automation,” he says. The technology can handle tasks from standard I/O and sensor connectivity to specialized applications such as synchronized motion and safety.

Origins

The development of EtherNet/IP can be traced back to the 1990s, a time when industry was still wrestling with introducing open industrial networks with an eye toward moving away from proprietary systems. It was then that Rockwell Automation developed the Control and Information Protocol, as CIP was initially known before being renamed to its current name of Common Industrial Protocol. Rockwell Automation would put this object-oriented communications protocol at the heart of two other open networking protocols, ControlNet and DeviceNet.

These two networks implement CIP in different ways. ControlNet is a fieldbus networking protocol that implements CIP over a concurrent-time division, multiple-access (CTDMA) data link layer. It offers precise determinism and permits both scheduled and unscheduled traffic, but didn’t go far because of its 5-megabaud speed limit. DeviceNet is faster, being a digital, multidrop fieldbus network protocol that applies CIP over controller area network (CAN) hardware.

By the late ’90s, the Ethernet age was well underway. The technology was already exploding in the office space, and the automation industry was thinking about how to use Ethernet in industrial networks. This led ControlNet International and ODVA to pool their resources to adapt CIP to Ethernet. The two organizations entered into a joint technology agreement in 2000, applied CIP to TCP, UDP, and IP, and jointly launched EtherNet/IP in 2001.

“By using Ethernet as the underlying physical layer, data can move faster with better uptime than with traditional CIP,” notes Mark Russell, tech application support manager at Allied Electronics and Automation (now known as RS to better reflect its operations as a brand of RS Group plc). “Once a fully Ethernet physical layer was established, we were able to evolve away from binary data that was stored in registers to a more object-oriented approach that allowed for quicker integration.”

He adds that IEC-61158 and 61850 standardized the protocol further. “That made communication between brands that support EtherNet/IP much more efficient,” he says.

A few years after EtherNet/IP was released, the joint technology agreement between ODVA and ControlNet International ended, and the two organizations merged, consolidating under the umbrella of ODVA. Today, ODVA manages all four CIP-based networks: EtherNet/IP, DeviceNet, and ControlNet, as well as CompoNet (which applies CIP on a time division, multiple access (TDMA) data link layer).

Though some in industry have expressed concern that EtherNet/IP’s development is closely held by Rockwell Automation, Fales notes that Rockwell is one of more than 375 industrial automation companies that belong to the ODVA. “Rockwell Automation remains heavily involved in the organization through its standard rights to participate as an ODVA member,” he explains. “The publication of the EtherNet/IP technology and its enhancements has been done through ODVA’s rigorous collaborative development and approval process.”

Continuing evolution

Since EtherNet/IP was introduced by ODVA, the standard has continued to evolve. For example, ODVA has exploited CIP’s object-oriented architecture to develop services and device profiles for real-time control of automation. “Over time, the addition of CIP extensions such as CIP Safety, CIP Security, CIP Sync, CIP Motion, and CIP Energy have greatly expanded the capability of EtherNet/IP,” says Fales.

Meanwhile, ODVA has also been enhancing EtherNet/IP for process automation. The most recent of these enhancements has been support for Ethernet-APL (advanced physical layer), an intrinsically safe version of Ethernet for field devices located in hazardous areas. This two-wire, single-pair Ethernet technology extends 10BASE-T1L (IEEE 802.3cg2019) and brings both power and communications to instruments as fast as 10 Mbit/s over cables as long as 1 km (IEC 61158). “Ethernet-APL devices adhere to IEC TS 60079-47 (two-wire intrinsically safe Ethernet) in order to ensure intrinsically safe ignition protection,” says Fales.

“The full extension of EtherNet/IP into the process industries,” he continues, “is critical to ensure that end users have a single industrial communication network for all of their potential automation applications, regardless of whether they are in the discrete, hybrid, or process markets.” He notes that NAMUR (an international association of process industry companies) named EtherNet/IP as one of the minimum binding requirements for the process industry.

Another way EtherNet/IP is evolving with the times is the development of a new CIP application profile for time-sensitive networking (TSN), a set of IEC/IEEE 60802 bridging standards now being developed and promulgated to allow time-coordinated and regular traffic to coexist on Ethernet.

Fales reports that the ODVA is participating in the development of the TSN standards and will release its new CIP application profile sometime after the first edition of the TSN standards is published later this year. At that time, end users will be able to natively implement the TSN application profile or leverage a gateway to allow for converged communication via TSN.

“Either approach will allow for fair network-level access with other IEC/IEEE 60802-compliant devices,” says Fales. “Existing EtherNet/IP devices can also work on TSN networks, but their quality of service on the wire may be degraded when compared to a non-TSN network.”

One of the benefits that TSN promises to bring to EtherNet/IP is the ability to adapt CIP Motion by aligning the network with a motion control planner using a common notion of time. Once CIP Motion and 60802 are aligned, network transport can be facilitated using scheduling as necessary to meet the needs of the network and coexist fairly with existing traffic.

Proven on 5G

Because EtherNet/IP relies on CIP at the application layer as well as IEEE standards, it has enjoyed some independence on the choice of physical communications medium. EtherNet/IP can be deployed on copper, fiber, fiber ring, or wireless technologies.

In fact, wireless support for industrial Private 5G has been recently demonstrated in a joint test bed conducted by Rockwell Automation, cellular-infrastructure provider Ericsson, embedded-device supplier Qualcomm, and network-service provider Verizon. Based on test results, the researchers concluded that 5G shows promise for augmenting, and even replacing, conventional wired connections within industrial networks.

The test bed was constructed using a Rockwell Automation GuardLogix safety controller to represent an area controller and Flex 5000 standard and safety (CIP Safety) I/O to represent skids, machines, and equipment. The radio access network infrastructure consisted of Ericsson’s mmWave spectrum base station and Private 5G core (3GPP Release-15, non-standalone, on-premise). A Qualcomm mobile test platform for data collection and traffic flow analysis served as an industrial 5G-to-Ethernet adapter.

“The test results demonstrate that the current state of industrial private 5G has low enough latency and jitter to support RPI [requested packet interval] settings that are better than the Rockwell Automation default settings for EtherNet/IP standard and safety I/O connections,” reports Wilcox. “These RPI settings will support many untethered, fixed industrial asset applications that use EtherNet/IP standard and safety I/O communications.”

Consequently, many new installations are no longer constrained by the need to install the costly wired infrastructure that has been required to connect skids, machines, and other tethered, fixed assets to an industrial network. “It’s a game changer in terms of cost, flexibility, sustainability, and time-to-market for industrial operations around the world,” says Wilcox.

The researchers plan to continue their investigation. For example, they have been evaluating EtherNet/IP time synchronization (CIP Sync) and distributed motion (CIP Motion) applications over 3GPP Release 16, standalone, industrial Private 5G. Wilcox reports promising results from an initial proof of concept.