As the energy industry digs down deep to get at unconventional oil and gas resources, they have to pull out all kinds of tricks. It’s not always enough to rely on the automation of old. They must move beyond the techniques used for conventional oil drilling, exploration and production.

In contrast to conventional oil, for example, the shale industry uses a lot of wells, flowing at lower rates. “The half-life of production on these wells is also extremely short. About 80 percent of the production happens in the first 12 months,” says Frank Whitsura, vice president and general manager, projects and automation solutions, for Honeywell Process Solutions (HPS). “They have to get the most out of it they can during its short life, and they’re creating wells at a very prolific rate.”

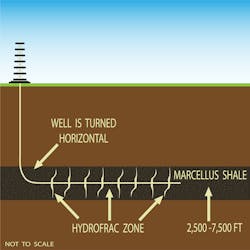

Because of the high number of wells, the I/O density coming out of shale sites is much higher than conventional well sites, notes Jim Scott, business development manager, oil and gas, for Rockwell Automation. “Historically, there’s a single well every quarter of a mile in traditional play,” he says. “A plane of shale rock that can go in multiple directions will have four, six, even up to 12 wells per well pad. With that comes the equipment—the separators, flare packages, metering systems that go with all of that. That I/O density, the controls requirement for those sites, is remarkably higher than it has been in the past because there are so many wells.”

Some of the automation comes from standards set by conventional oil and gas, and some comes simply from drilling companies looking around to see what’s working for their neighbors. There’s little in the way of standardization at this point.

Rachel Phillips Herrick, a production engineer at Goodrich Petroleum, an independent oil and natural gas exploration, development and production (EDP) company, describes a situation in which automation developed on a fairly piecemeal basis. “We go with, ‘Oh, my boss used this kind of metering and measurement on an older, conventional field, so we’re just going to do it here, too.’ Then we start retrofitting other instruments to that,” she says.

The lack of standardization is a key factor that differentiates conventional and unconventional oil fields. Some big oil companies might follow their own standards, but many companies aren’t even doing that, and there is certainly little standardization across the industry, says Sudhir Jain, an oil and gas consultant for Emerson Process Management.

“It’s really pretty messy, with very little standardization,” Scott says.

This is even more the case with older fields, Phillips Herrick says. She describes Goodrich’s Eagle Ford site in South Texas as the “old way.” “Our Mississippi play is a little more advanced,” she says. Goodrich began exploring the Tuscaloosa Marine Shale site in Mississippi and Louisiana in 2012, designing in more advanced technology from the ground up, although Phillips Herrick says, “It still has a ways to go.”

The standardization picture has been changing even just within the last three to six months, according to Brandon Spencer, vice president of chemical, oil and gas for the U.S. at automation provider ABB. “With different players coming in and trying to be really efficient and fast, they do what works at that time,” he says. “But as consolidation happens, we start seeing more standardization. They’re using the vendor list more, instead of just who’s local. They can begin to leverage that across all of the installed base.”

Standardization will be key to increasing safety, yield and profitability, Scott notes. “Of course I’d love for them to standardize on my product, but the answer is bigger than that,” he says. As shale players standardize more on well pad design, processes, controls…they begin to see a larger degree of reciprocity. “They end up with a much safer, easier-to-use, easier-to-maintain facility. That will increase profitability and yield.”

Whitsura expects the automation picture to change over the next several years, and by 2020 he predicts there will be more consolidated wells and operations, centralized control, integrated operations, more remote operations, and increased yield and profitability.

In general, upstream shale operations use much simpler automation. “It’s not about optimizing what you’re doing, but more about keeping it running, deploying it quickly, and getting the information that you need from it,” says Lee Swindler, program manager for system integrator Maverick Technologies.

Emerson’s Jain has been working in the instrumentation field for close to 30 years, primarily in conventional oil, and has found that so far unconventional oil like shale is using much the same automation as conventional, including separator control, level control, temperature control, etc.

“Whether they fit properly or not is a different story,” he says, pointing to shale’s multiple wells on the same well pad connected together rather than the one or two operators typically managed. “The main issue was: Can you do the things the way you were doing in conventional? They were getting the job done, but they were facing a lot of issues. They were not able to find out whether the wells were producing correctly.”

>> Read more about how automation is developing in the shale industry when Automation World publishes its May issue next month.

Leaders relevant to this article: