The OPC Foundation has joined the advanced physical layer (APL) for Industrial Ethernet project group and is collaborating with ODVA and Sercos International to develop a new generation of a best-in-class industrial motion technology.

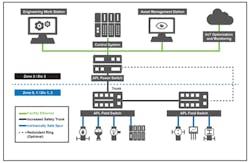

Ethernet-APL describes a physical layer for Ethernet communication technology developed for the requirements of the process industries to deliver industrial communication at high speeds over long distances. The supply of power and communication signals in Ethernet-APL are delivered via a common single, twisted-pair (2-wire) cable. This technology also is designed to provide protective measures for safe use within hazardous areas. Based on IEEE and IEC standards, Ethernet-APL reportedly supports any Ethernet-based automation protocol and is expected to develop into a single, long-term stable technology for the entire process automation community.

The OPC Foundation says its decision to join the APL project group is closely related to its strategy to extend OPC UA to the field level communications (FLC) in discrete and continuous manufacturing.

The APL Project was originally established in 2018 and is backed by the FieldComm Group, ODVA, OPC Foundation, Profibus and Profinet International, as well as automation technology suppliers ABB, Emerson, Endress+Hauser, Krohne, Pepperl+Fuchs, Phoenix Contact, Rockwell Automation, Siemens, Vega, and Yokogawa.

In addition to its Ethernet-APL announcement, The OPC Foundation also unveiled its collaboration with ODVA and Sercos International to develop what it calls “a new generation of a best-in-class motion technology for industry.” According to the OPC Foundation, this new motion technology will initially be published as OPC UA Motion, with subsequent updates to the Sercos technology and the CIP Motion technology for EtherNet/IP. This new technology will reportedly provide “a flexible architecture for distributing motion control features between controllers and drives based on a common information model for motion devices, such as PLCs/motion controllers, standard drives/frequency converters, positioning drives, servo drives, motion encoders, motor starters, and power supplies.”

“OPC UA Motion is an important extension to the OPC UA Framework, ensuring—in combination with OPC UA Safety, deterministic communication, and Ethernet-APL/SPE—semantic interoperability, not only for the controller-to-controller and controller-to-device use cases in factory and process automation, but also supporting OPC UA as a fully scalable technology from the sensor across all levels to MES/ERP and to the cloud,” says Lutz.

As part of this collaboration, ODVA and Sercos International are committed to building upon their existing collaborations with the OPC Foundation and to providing users of EtherNet/IP and Sercos with improved motion technology.

“The work between ODVA and the OPC Foundation on OPC UA Motion and the OPC UA companion specification for CIP will ensure that vendors and end users can take advantage of best-in-class device, cloud, and enterprise level services in both the machine automation and process industries with EtherNet/IP and OPC UA,” says Dr. Al Beydoun, president and executive director of ODVA.

Leaders relevant to this article: